The History of CNC Turning Machine

John T. Parsons (1913-2007) of Parsons Corporation in Traverse City, MI, is considered the trailblazer of mathematical control, the forerunner to the popular CNC Turning Machine. John Parsons has been alluded to as the daddy of the 2d current unrest for his work. He expected to make convoluted eggbeater millings and immediately understood that the long run of delivering was interfacing machines to PCs. Nowadays, CNC-made parts are, in many cases, found in almost every industry. Because of CNC Turning Machine, we’ve fewer exorbitant products, more grounded public protection, and the following standard of living than is plausible in a non-industrialized world. During this article, we’ll investigate the beginnings of the CNC machine, contrasting sorts of CNC machines, CNC machine programs, CNC Machine Job Work and standard practices by CNC machine shops.

Machines Meet pc

In 1946, “PC” implied a Hollerith card worked computation machine. But Parsons Corporation had exclusively made one propellor; John Parsons persuaded industrialist eggbeater that they might fabricate phenomenally exact layouts for propeller get together and produce. He completes up concocting a punch-card PC procedure to work out focuses on a helicopter rotor milling. Then, at that point, he had administrators flip the wheels to those focuses on a Cincinnati milling machine. He controlled a challenge for the name of this new technique and gave $50 to the one that instituted “Mathematical Control” or Old North State.

In 1958, he recorded a patent to join the pc to the machine. His application showed up 90 days before MIT, which was working on the possibility that he had begun. MIT utilized his plans to shape the primary instrumentality, and Mr. Parsons’ retailer (Bendix) sub-authorized to IBM, Fujitsu, and GE, among others. The NC idea was delayed to get on. Per Mr. Parsons, the people who greed the idea were PC individuals instead of delivering individuals. By the first 1970s, however ever, the actual USA advocated the use of Old North State PCs by building and renting them to different makers. The CNC regulator developed in lined up with the PC, driving greater efficiency and robotization into assembling processes, especially machining.

What’s CNC Turning Machine?

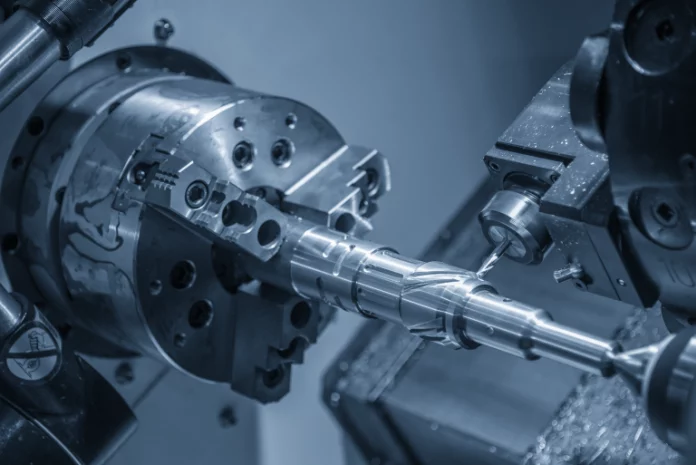

CNC Turning Machine are making parts of the world for basically every industry. They produce things out of plastics, metals, aluminum, wood, and many option-depleting materials. “CNC” represents pc Numerical Control, but nowadays, everyone calls it CNC. All in all, how can one blueprint a CNC Turning Machine? All programmed movement the board machines have three essential parts – an ordering capability, a drive/movement framework, and a criticism framework. CNC machining is the strategy for utilizing a PC-driven machine to give a region out of solid material in an entirely unexpected shape.

The CNC relies upon computerized headings at times made on pc helped to create (CAM) or pc helped style (CAD) bundles like SolidWorks or Maste CAM. The product composes G-code that the regulator on the CNC Turning Machine will peruse. The pc program on the regulator deciphers the look and moves cutting apparatuses and works on different tomahawks to cut the necessary structure from work. The programmed cutting technique is way speedier and has a ton of right than a manual development of instruments and workpieces that are finished with switches and cogwheels on more established gear. Present-day CNC Precision Components hold various apparatuses and assemble many kinds of cuts. The number of planes of development (tomahawks) and the number and sorts of instruments that the machine will get to precisely all through the machining system check muddled a CNC workpiece can make.

A method for utilizing A CNC Turning Machine

CNC mechanical engineers ought to acquire abilities in each programming and metal-attempting to shape full utilization of the capacity of a CNC Turning Machine. Specialized exchange resources and circumstance programs frequently start understudies on manual machines to initiate an identification with a method for cutting metal. The apprentice should be prepared to imagine each of the three aspects. Nowadays, the bundle makes it more straightforward than at any other time to make convoluted halves because the part structure is, in many cases, moved almost then apparatus techniques can be prescribed by programming to make those parts.

Type of bundle conventionally utilized in the CNC Machining technique

PC helped Drawing (CAD)

Computer-aided design programming is the beginning line for most CNC projects. There are numerous elective CAD bundle bundles, but all are wont to create plans. Popular CAD programs typify AutoCAD, SolidWorks, and Rhino3D. There are cloud-based CAD arrangements, and a couple of supply CAM abilities or incorporate with CAM programming higher than others.

PC helped deliver (CAM)

CNC Turning Machine ordinarily use programs made by CAM programming. CAM licenses clients to arrange a “task tree” to organize work processes, set device techniques, and run cutting recreations before the machine will any genuine cutting. Typically CAM programs fill in as additional items to CAD programming and produce g-code that tells the CNC devices and work moving parts any place to go. Wizards in the CAM bundle fabricate it more straightforwardly than any time in recent memory to program a CNC Turning Machine. Popular CAM programming incorporates Mastercam, milling cam, One CNC, HSMWorks, and Solidcam. Mastercam and milling cam represent half of the excellent completion CAM portion of the overall industry per a 2015 report.

Apart from that, if you are interested to know about Cold Press Oil Machine Commercial then visit our Business category.